3D Modeling of “Bad Ore”

Improving Near-Term Forecasting at an Arizona Mine

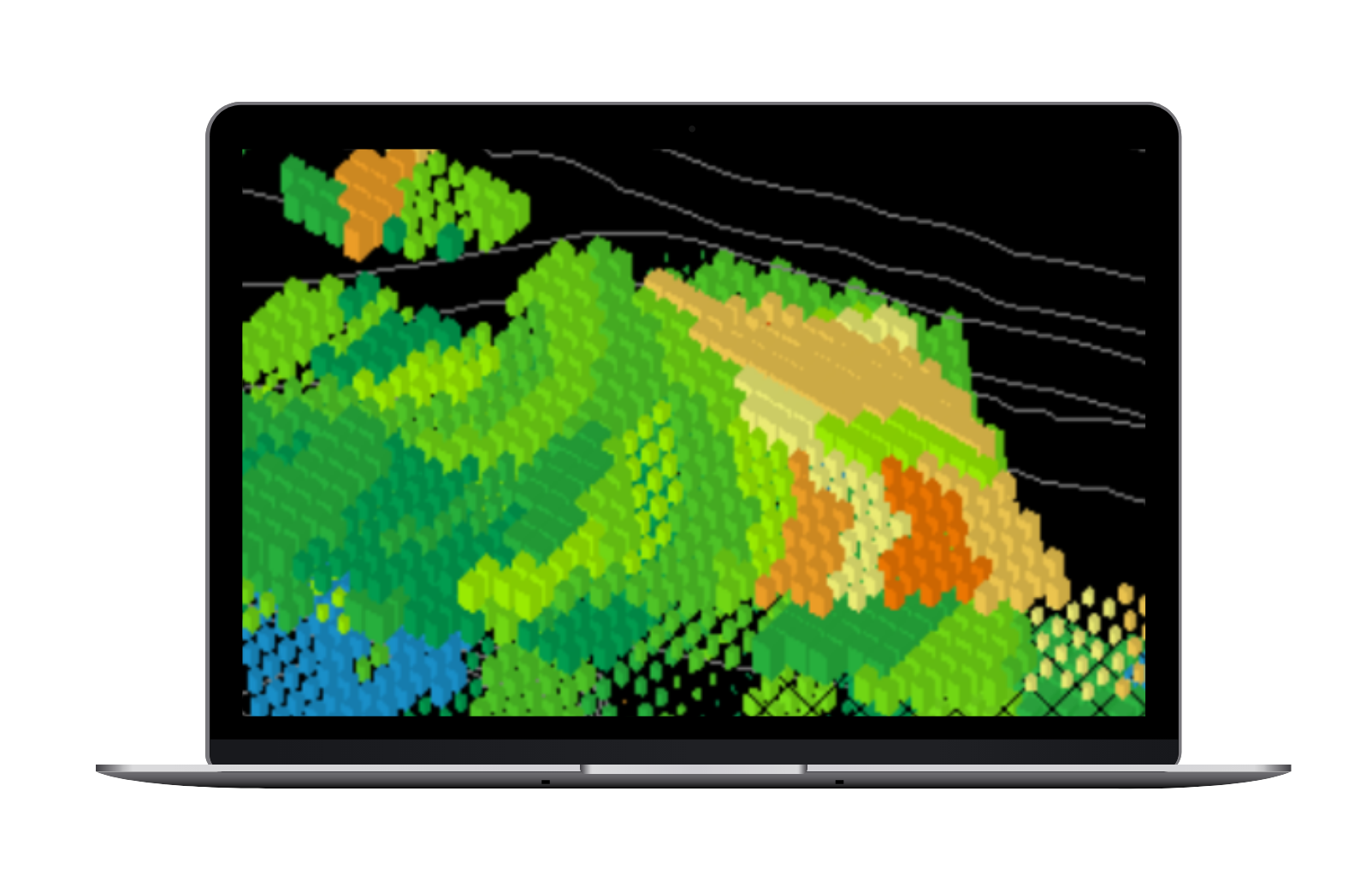

Screen capture zoomed in on a similar 3D block model.

Photograph showing Bagdad Mine open pit in the background and surrounding mesas. Taken from Lawler Peak, Arizona. 2013, Sarah Nagorsen

Spatial Modeling for Better Mining

In 2011 there were murmurs of “bad ore” at the Bagdad Copper mine in western Arizona. Some ore didn’t grind well and turned into identically sized rock balls - unable to break down further in the mill. Some ore had low copper recoveries in the flotation circuit.

The metallurgical group tested samples for clues on how to optimize crushing, grinding, and flotation as to extract the most copper and molybdenum and decrease waste. But with haul trucks dumping ore from different areas of the mine into the primary crusher, there was no definitive way to tell where the bad ore came from.

As project geologist for the Mine-to-Mill Block Model, I repurposed a 3D block model project from a partner mine to combine technical, metallurgical, and geological datasets at the Bagdad Mine. Correcting for lag times and ore blends, we were able to see temporal process data (how the ore performed in the mill) plotted spatially in the ore’s source location. This model helped us better forecast production and provided insights on location and potential geological characteristics of “bad ore.”